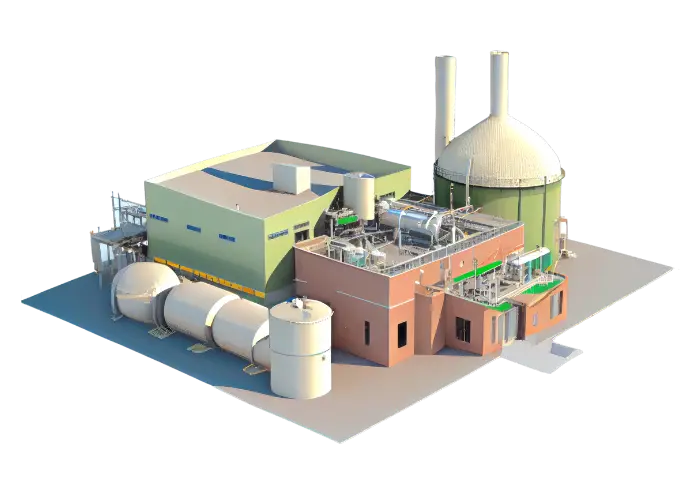

1. Resource Recovery Plants

Overview

Chemical Extraction

& Refining-

Pure Water

Recovery

Deur is leading the change to transform every ordinary wastewater treatment plant into a sustainable source of high-purity water. This change promises two big outcomes for the world – 90% reduction in natural resource contamination and 30% extra supply of clean drinking water.

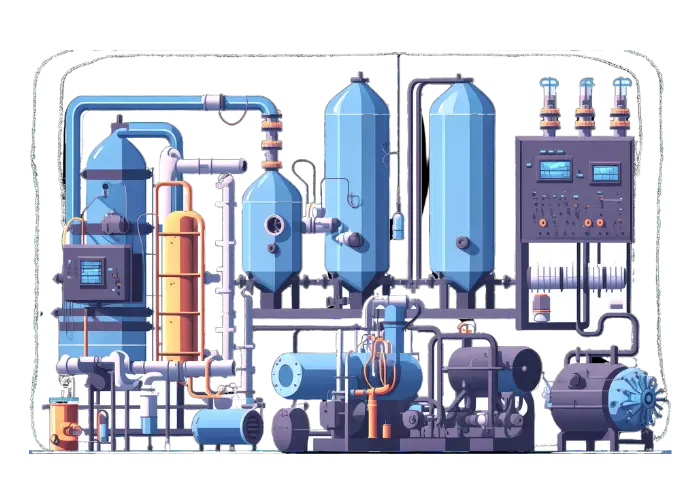

Our Resource Recovery solution is a revolutionary approach to extract many valuable resources that are otherwise being discarded along with the waste water. These resources include pure water, chemicals, gas and metals. The reclaimed resources can be reintegrated as inputs within the facility or repurposed as market commodities, offering additional avenues for revenue gains

The Deur chemical extraction process DeurRR embraces an environmentally friendly methodology by harnessing the distinctive “Panchatatva” process. This comprehensive approach involvesNeutraBlend, IonicSort, SpinFlex, PureStain and CrystalVapour Pro processes. Through the implementation of this exclusive method, Deur effectively extracts and reclaims both chemicals and water, demonstrating a commitment to eco-conscious practices.

Extracted refined chemicals are then primed for reuse, promoting a circular economy that reduces reliance on new raw materials. This not only provides industries with a sustainable supply of high-quality chemicals but also aligns with environmental sustainability objectives.

- Up to 95% Recovery of Pure Chemicals / Nutrients

- 30-40% reduction in plant operations cost

- 3-5 years payback period for metal and chemical recovery plant

A Pickling factory faced a significant issue with Pickling sludge. Through our “Panchatatva” process, a Proof of Concept (POC) modelling revealed potential annual savings of around 2 crores by recovering valuable chemicals.

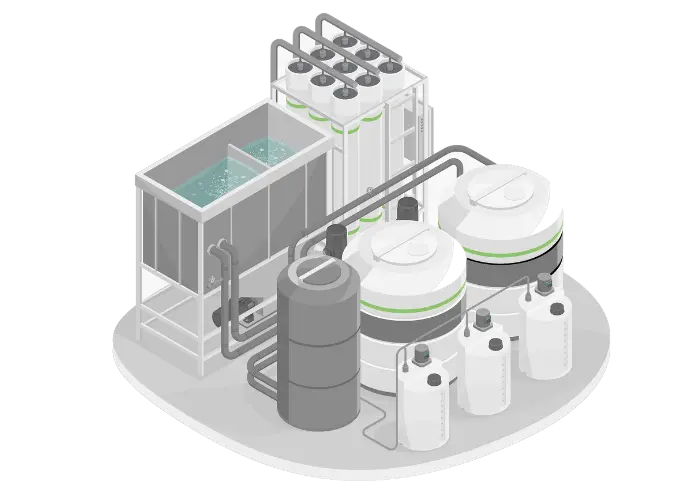

Deur offers DeurPWR, a ground breaking advanced water treatment technology designed to achieve unprecedented levels of purified water recovery from the waste water. DeurPWR surpasses traditional RO recovery limits by employing a modular and optimized configuration of membrane elements along with fine particle shortwave reactor. This technology consistently attains excellent water recovery rates even when dealing with the most intricate industrial wastewater.

- Up to 90% recovery of clean and potable water

- Reduced energy consumption by 30-40%

- 30-40% Maintenance & Operating Cost

A prominent multinational company implemented DeurPWR technology, effectively treating 90,000 litres of Reverse Osmosis (RO) reject water daily. Through this innovative approach, an impressive 85% of the treated water is reclaimed as clean, potable water.

2. Industrial Water Treatment

Overview

Process Water

Treatment-

Wastewater

Recycle & Reuse -

Demineralisation

Plant

We offer tailor-made, high-performance industrial water treatment solutions specialised to match the distinct qualities of effluents generated by your plant.

There are many complex challenges associated with the wastewater treatment that are usually remain unaddressed in conventional solutions such as regulatory compliances, sustainability of the reuse over years and productivity of the plant operation. Our approach guarantees an efficient and effective way to take care of all such challenges.

DeurGWR, the Deur Groundwater Remediation plant, distinguishes itself through advanced technologies, guaranteeing effective treatment and purification of groundwater. This ensures the water supplied through DeurGWR purification strictly meets all the ionic & organic chemical purityrequirements for industrial and commercial production, thus enabling manufacturers to achieve a flawless production process.

DeurGWR is not only energy-efficient but also operates on solar power, emphasizing sustainability and reducing operational costs. This dual capability aligns with eco-friendly practices, promoting both cost savings and long-term environmental impact.

- 90% removal of contaminates from input water

- 100% compliance with specified clean water requirements

- Reduced Operational Expenses

- High energy efficiency due to solar-power

A well-regarded Greenhouse Farming industry used DeurGWR solution to generate water with precise water quality specific to pH, Electrical Conductivity, and hardness defined which facilitated increased crop yields for the farmers making them profitable in less than six months.

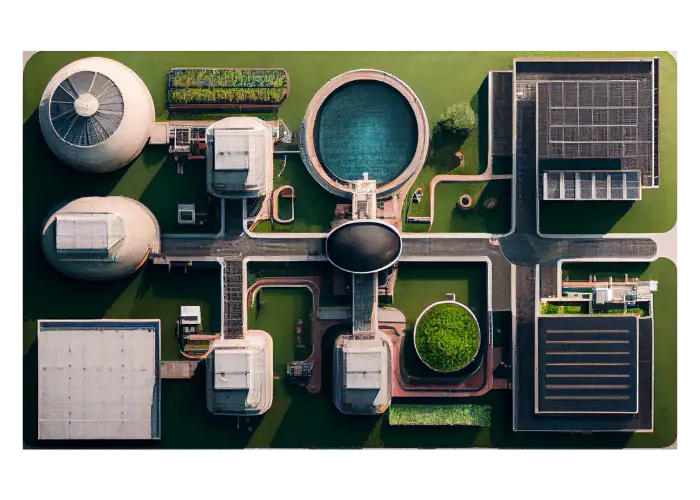

Deur Waste Water Filtration (DeurWWF) is a crucial process for purifying wastewater prior to release or reuse. This innovative approach employs a modified process, achieving high-rate pollutant removal within a compact footprint. The Reactor, through specialized cascades and aeration sequences, effectively addresses municipal and heavily loaded industrial wastewaters biologically.

Commencing with preliminary treatment to remove debris, the process advances to primary treatment, facilitating solid-liquid separation and sludge formation. Subsequent stages include secondary treatment, utilizing biological processes for organic matter breakdown, and tertiary treatment, incorporating advanced filtration and disinfection. This comprehensive approach guarantees pathogen removal, ensuring the water is safe for discharge or reuse.

Distinguished by its robustness, this method surpasses typical activated sludge processes. It demonstrates superior capability in handling elevated pollutant concentrations while minimizing sludge production compared to conventional biological wastewater treatment technologies.

- Up to 90%recovery of clean and potable water

- 100% compliance with specified Industrial water requirements

- Upto 40% reduction insludge Production

- High rate of pollutant removal

A food processing industry in Hosur releases 10,000 litres of wastewater daily to the Common Effluent Treatment (CET) facility, characterized by a pH of 3.2, COD of 74480 mg/l, and BOD of 24000 mg/l. Through the implementation of DeurWWF, the industry achieves daily recovery of 80% clear water for reuse.

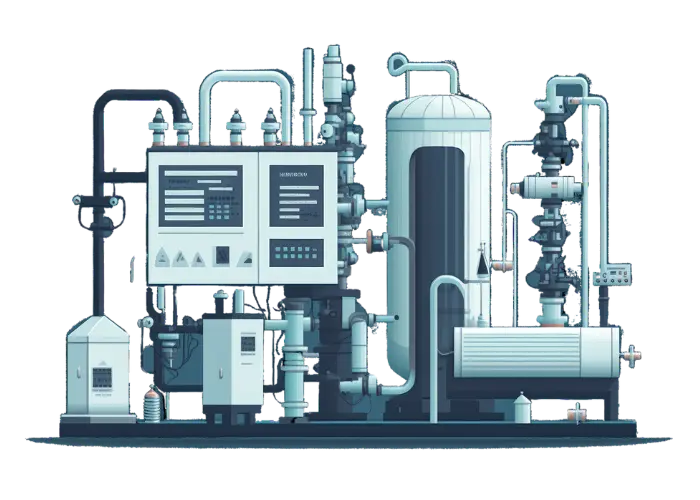

Deur demineralization plant, is an industrial facility engineered to eliminate minerals and salts from water, creating demineralized or deionized water. Employing ion exchange processes, this system selectively eliminates positively and negatively charged ions, yielding water nearly devoid of most ions. This purified water, of paramount importance in industries such as power generation, pharmaceuticals, and electronics manufacturing, is employed in processes where the presence of minerals could negatively impact equipment or operations.

- High Purity water Production

- Scaling & Corrosion prevention

- Enhanced Product Quality

- Sustainable water Management

A leading Bangalore hospital, conducting 10 dialysis sessions hourly uses DeurDM plant togenerate high-purity water, totally free from contaminants which makes is completely safe to use for their patients.